Introduction

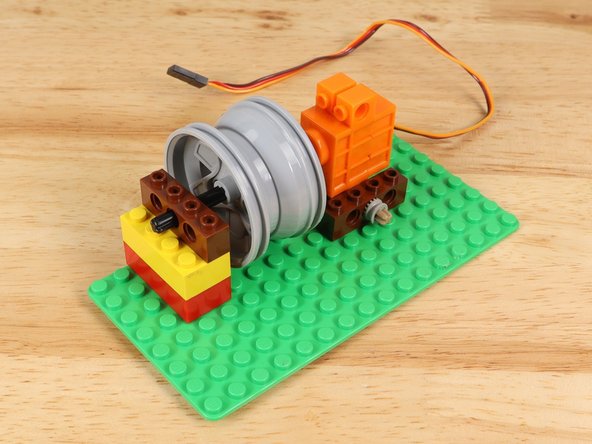

We'll build a simple LEGO-based winch mechanism using a 360 degree continuous rotation servo that can be used with any microcontroller.

Tools

No tools specified.

Parts

- Brick Compatible 360 Degree Servo

- LEGO Wheel 43.2mm D. x 26mm Technic Racing Small with 3 Pinholes (41896)

- LEGO Axle 6 (3706)

- LEGO Axle Connector (Smooth with 'x' Hole) (59443)

- LEGO Axle 4 with End Stop (87083)

- LEGO Technic Brick 1 x 2 with Hole (3700)

- LEGO Technic Brick 1 x 4 with Holes (3701) × 3

- LEGO Technic Bush 1/2 with Teeth Type 1 (4265)

- String

Video Overview

-

-

As with all LEGO projects a variety of parts can be used. We've listed all the parts we chose but you should use what works, or what you already have on hand when possible.

-

For instance, here are two alternative wheels/rims that could work.

-

-

-

Any wheel/rim with an "H" or "V" shaped groove should work. Avoid the ones with raised ribbing in the groove part.

-

Besides the specified LEGO parts you'll need a LEGO baseplate, a few standard LEGO bricks, a 360 degree continuous rotation servo, and some string.

-

-

-

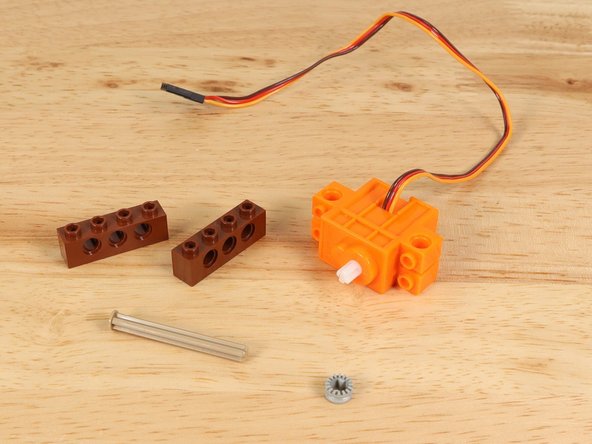

We'll start by adding some "feet" to the servo so we can attach it to the baseplate.

-

Use the following parts:

-

LEGO Technic Brick 1 x 4 with Holes (3701) You'll need two of them.

-

LEGO Axle 4 with End Stop (87083)

-

LEGO Technic Bush 1/2 with Teeth Type 1 (4265)

-

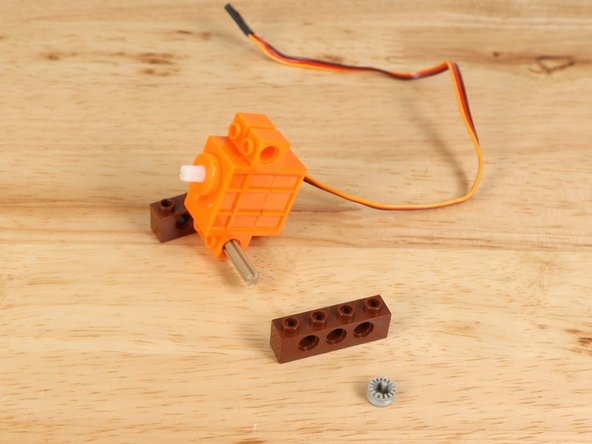

-

-

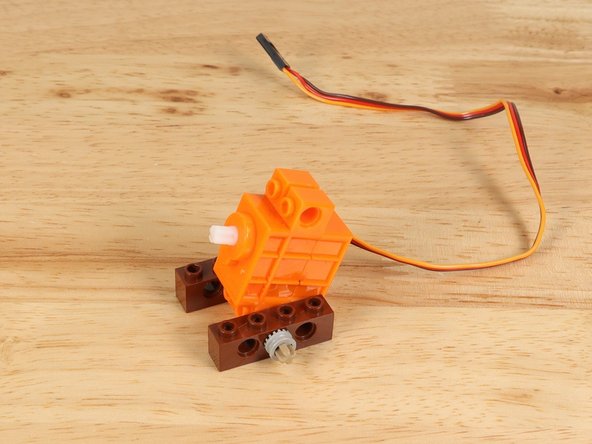

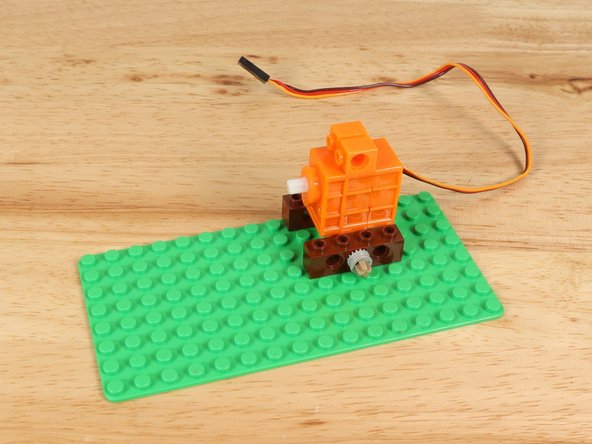

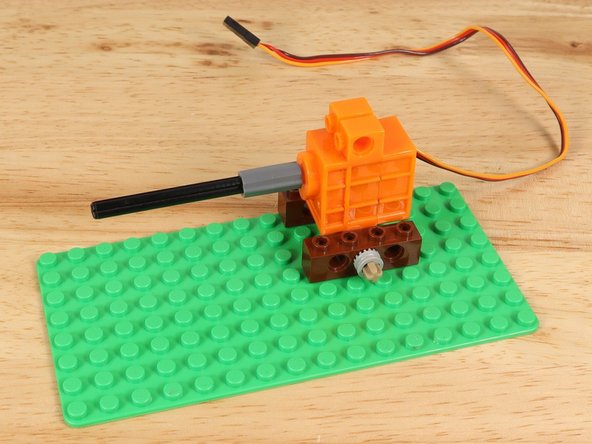

Once you have the "feet" for your servo you can attach it to a LEGO baseplate.

-

Make note of the orientation of the servo. Since the shaft is not centered you want it higher up in the assembly.

-

-

-

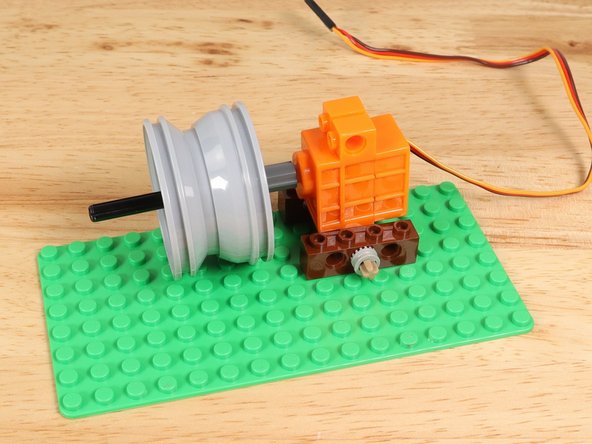

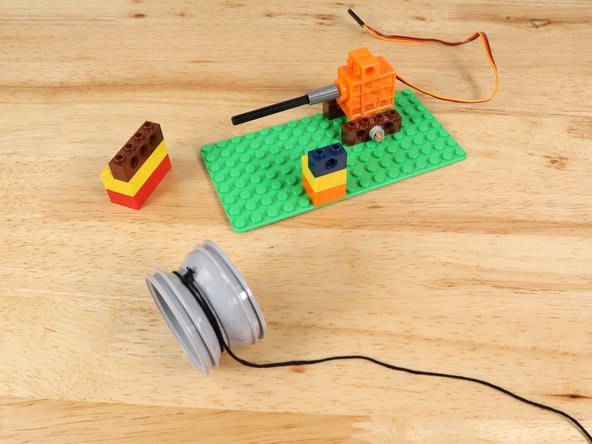

Next we'll attach the shaft and wheel/rim to the servo. You'll need an axle connector added to the servo shaft to start.

-

Use the following parts:

-

LEGO Axle Connector (Smooth with 'x' Hole) (59443)

-

LEGO Axle 6 (3706)

-

LEGO Wheel 43.2mm D. x 26mm Technic Racing Small with 3 Pinholes (41896)

-

Don't worry about the position of the wheel/rim on the shaft, since we can slide it into the correct position later.

-

-

-

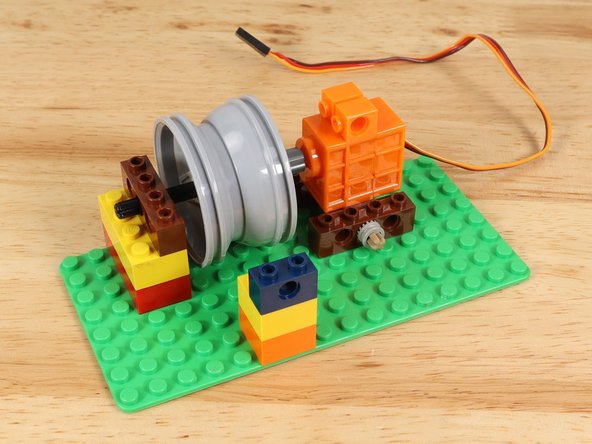

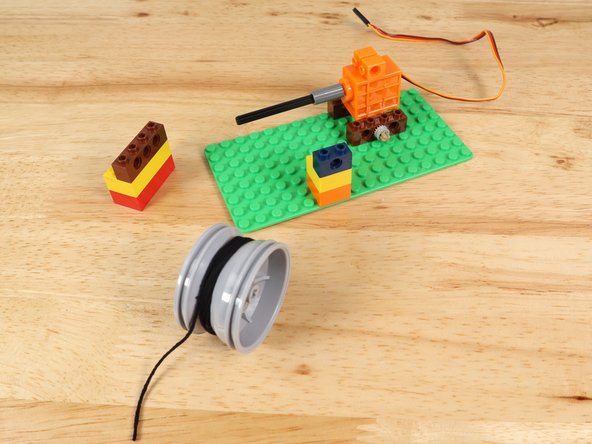

Next we'll add the parts to hold up the other side of the axle.

-

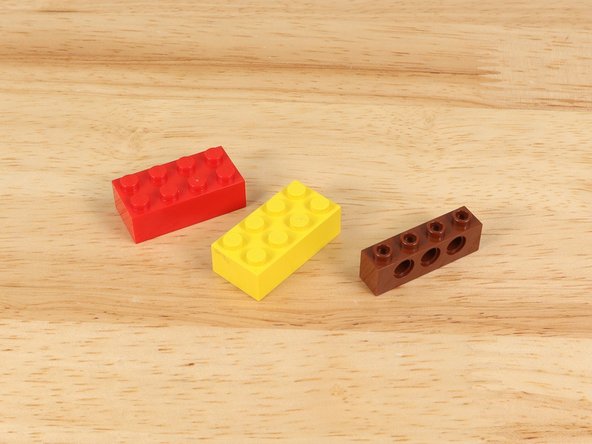

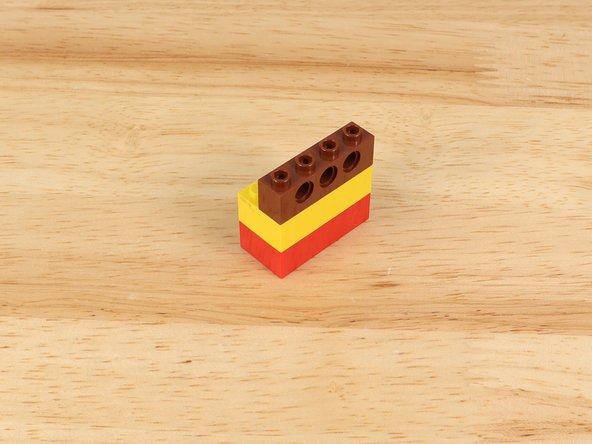

Grab two standard LEGO bricks and another LEGO Technic Brick 1 x 4 with Holes (3701).

-

Once assembled place it on the baseplate to hold the axle in place.

-

-

-

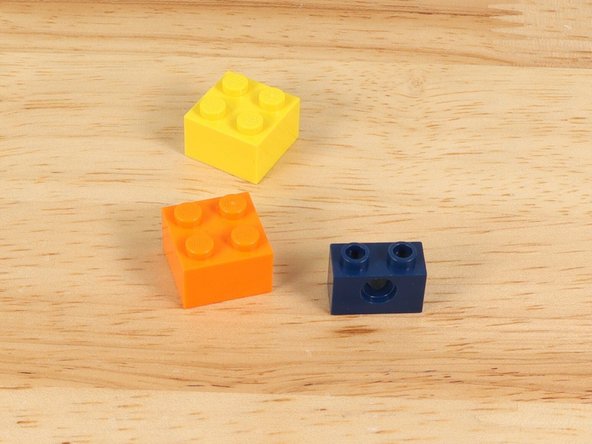

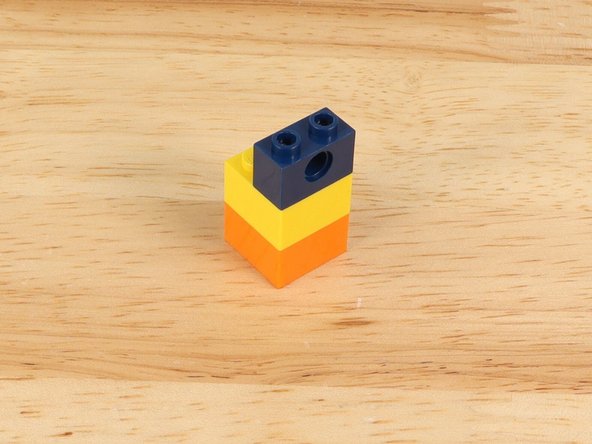

Next we'll add a simple guide for the string to feed through so it doesn't get tangled.

-

We used two small LEGO bricks and a LEGO Technic Brick 1 x 4 with Holes (3701).

-

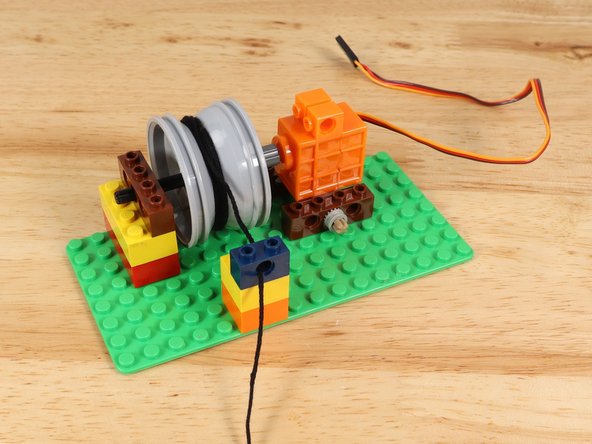

Line it up with the wheel/rim as close as you can, then slide the wheel/rim so it is centered to match the guide hole.

-

-

-

If everything looks right you can pull the wheel/rim off to add on some string.

-

Tie the string tight onto the wheel/rim and wind it around a few times.

-

If your string isn't wound enough times it may not wind up properly if you let too much of it out. You can also add a small piece of tape to hold the string in place if your knot is not tight enough.

-

Place the wheel/rim back onto the axle and feed the string through the guide hole.

-

Your winch is ready to go!

-